Outer Rotor Motors

Home » Product Range » Outer Rotor Motors

-

Outer Rotor Motors are specified for high power density applications. There is a bigger active force radius from the winding in the middle of the motor that creates more torque than standard BLDC motors with an equal external diameter.

STRUCTURE OPTIONS

With the rotor structure, the self-cooling fan design allows the motor to run at high load density points with low rise in temperature. This increases the power density and reduces the weight of the motor. It is an optimal choice for tools that need to be lightweight for use, like handheld or back pack applications. The stator structure offers a stronger overload capacity and can pass a higher current . The winding is wound by a single wire that is arranged neatly and has a higher slot filling rate.

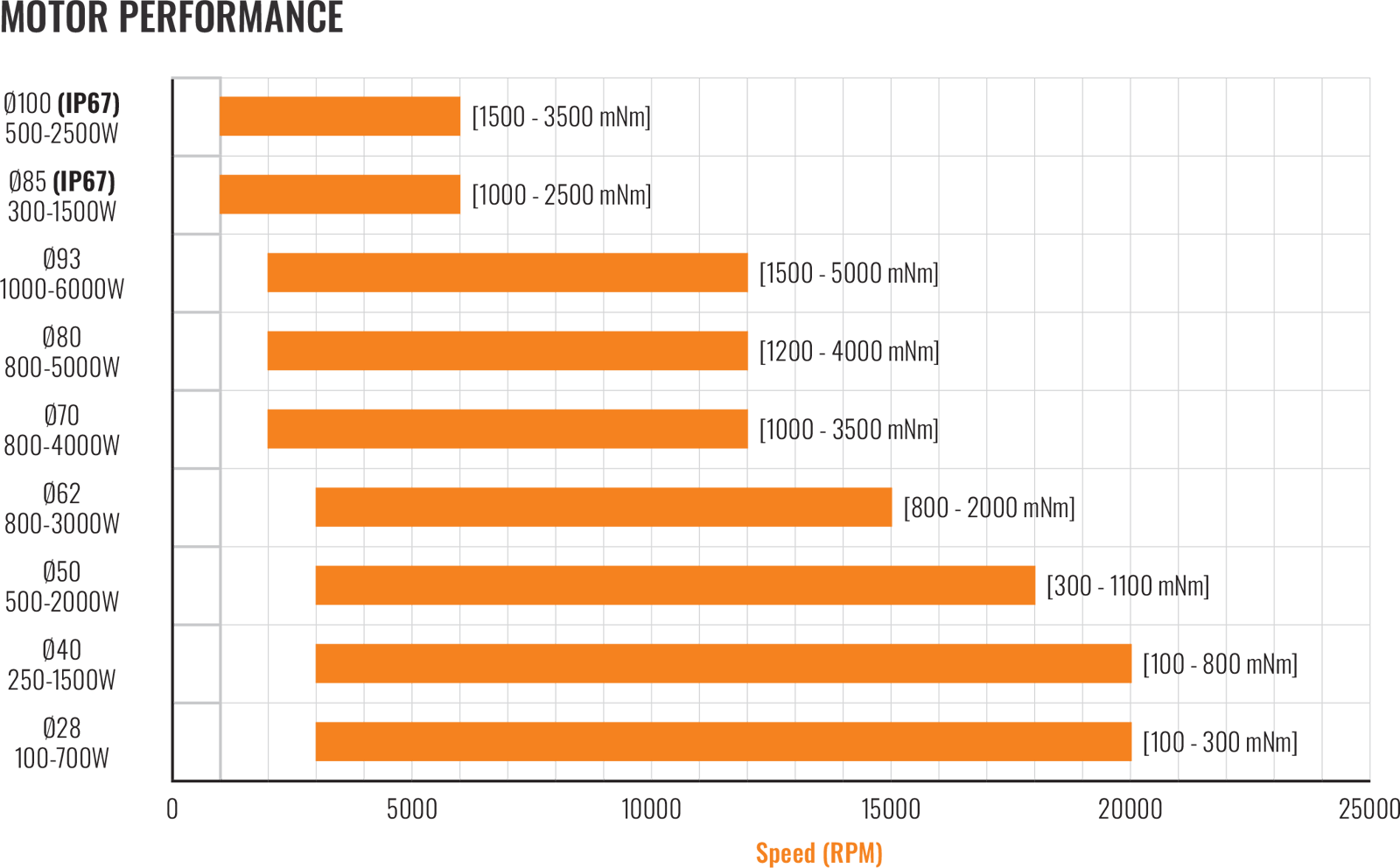

STANDARD PLATFORMS – OUTSIDE DIAMETER

Ø28mm , Ø40mm, Ø50mm, Ø62mm, Ø70mm, Ø80mm, Ø85mm, Ø93mm, Ø100mm

Outer Rotor Motor range

| Outside diameter (mm) | Peak Power (@) | Speed Min (RPM) | Speed Max (RPM) | Range Speed | Torque (mNm) |

|---|---|---|---|---|---|

| Ø28 100-700W |

700 | 3,000 | 20,000 | 17,000 | 100 – 300 |

| Ø40 250-1,500W |

1,500 | 3,000 | 20,000 | 17,000 | 100 – 800 |

| Ø50 500-2,000W |

2,000 | 3,000 | 18,000 | 15,000 | 300 – 1,100 |

| Ø62 800-3,000W |

3,000 | 3,000 | 15,000 | 12,000 | 800 – 2,000 |

| Ø70 800-4,000W |

4,00 | 2,000 | 12,000 | 10,000 | 1,000 – 3,500 |

| Ø80 800-5,000W |

5,000 | 2,000 | 12,000 | 10,000 | 1,200 – 4,000 |

| Ø93 1,000-6,000W |

6,000 | 2,000 | 12,000 | 10,000 | 1,500 – 5,000 |

| Ø85(IP67) 300-1,500W |

1,500 | 1,000 | 6,000 | 5,000 | 1,000 – 2,500 |

| Ø100(IP67) 500-2,500W |

2,500 | 1,000 | 6,000 | 5,000 | 1,500 – 3,500 |

Contact Us for more information, or if you want us to review your application.